How much is laser cutting per hour

Another consideration is the fiber laser’s briefcase-sized modules—they allow for redundancy. If one module has a problem, the resonator doesn’t shut down completely. The fiber laser is redundant in a way that the other modules can produce more power temporarily to support the down module until repairs can be completed—which, by the way, can be done in the field. Other times the fiber resonator can continue producing reduced power until repairs can be made. Unfortunately, if a CO2 resonator has an issue, the entire resonator is down, not just in a reduced-power mode.

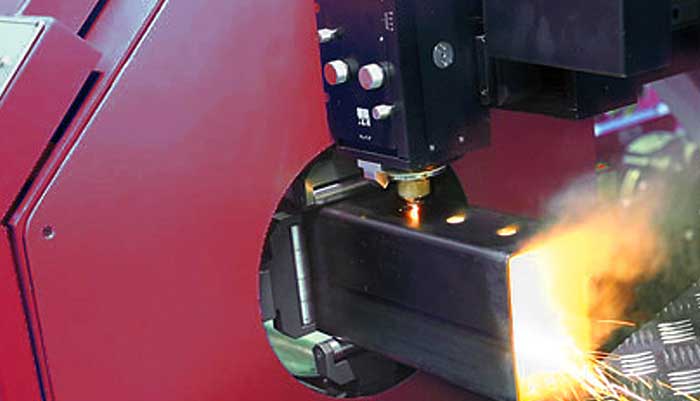

The StarFeed is an automated loader/unloader for the StarCut Tube laser cutting machine and is available in sizes S and L. This combination allows fully automated dry or wet cutting of tubes from 1-20 mm diameter. The StarFeed L stores up to 48 tubes and even allows the processing of oval tubes. Its sensor-controlled gripping unit avoids damage. The end result is a big increase in productivity.